Manufacturing

AI-Driven Solutions for Manufacturing Supply Chains in India

India’s manufacturing sector is at the heart of its industrial growth, poised for a transformational shift as it embraces advanced technologies to enhance efficiency, reduce costs, and scale production. As businesses face the increasing demands of global supply chain complexities, market volatility, and customer expectations for on-time delivery, AI-driven technologies provide the roadmap for success. At Qualins’ Business AI Digital Factory, we integrate cutting-edge AI solutions with ERP systems, Enterprise Data Management, Digital Workspaces, Edge Computing, and Industry 4.0 to optimize manufacturing supply chains, ensure operational excellence, and achieve sustainability.

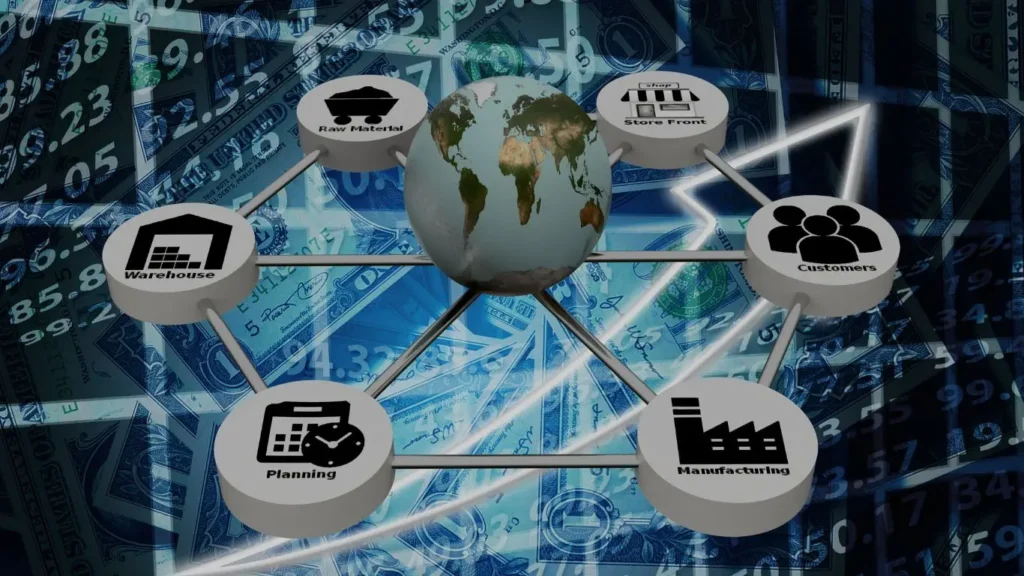

1. AI-Driven ERP Framework for Manufacturing Supply Chains

framework enables organizations to unify their supply chain, inventory management, production, logistics, and procurement processes into a single, integrated system, providing end-to-end visibility and control.

- End-to-End Supply Chain Visibility: With AI-driven insights, manufacturers can monitor supply chain processes, from raw material procurement to final product delivery, ensuring transparency, reducing delays, and enabling faster response times to market changes.

- Demand Forecasting & Inventory Optimization: AI models analyze historical data, market trends, and external factors to predict demand fluctuations and optimize inventory levels, reducing overstocking and stockouts, and improving working capital management.

- Supplier & Vendor Management: Our AI-based solutions enable manufacturers to evaluate and monitor suppliers in real-time, ensuring reliability, cost-effectiveness, and compliance. This enhances supplier relationships and facilitates strategic procurement decisions.

With AI-powered ERP solutions, manufacturing companies in India can significantly improve their supply chain resilience, enhance operational agility, and streamline their global sourcing processes.

2. AI-Driven ERP Framework for Manufacturing Supply Chains

The manufacturing sector generates vast volumes of data at every stage of the supply chain—ranging from production line monitoring, logistics, and inventory management, to demand signals and market intelligence. Our AI-enhanced Enterprise Data Management (EDM) framework empowers manufacturers to organize, analyze, and extract actionable insights from this data, driving data-driven decisions and operational excellence.

- Integrated Data Streams: AI harmonizes data from disparate sources, including IoT sensors, machine data, logistics tracking, and ERP systems, enabling a comprehensive, real-time view of supply chain performance.

- Predictive Analytics for Production & Maintenance: Our AI models predict equipment failures, identify bottlenecks in production lines, and forecast supply chain disruptions, allowing manufacturers to implement proactive strategies and improve predictive maintenance.

- Supply Chain Risk Management: With AI-driven risk assessment models, manufacturers can anticipate disruptions caused by natural disasters, geopolitical shifts, or supplier failures, and take preventive actions to minimize disruptions.

Through AI-powered EDM, manufacturers can gain deeper visibility into their operations, make smarter supply chain decisions, and enhance their competitive advantage.

3. AI with Digital Workspaces for Manufacturing

As manufacturing companies in India increasingly move towards digitalization, fostering seamless collaboration and real-time information sharing becomes crucial. Our AI-powered Digital Workspaces allow manufacturing teams, suppliers, and other stakeholders to connect and collaborate in real time, improving decision-making and operational efficiency across the supply chain.

- Collaborative Decision-Making Tools: AI-powered digital platforms enable production teams, supply chain managers, and procurement specialists to collaborate on forecasts, order processing, and material planning, ensuring seamless communication and alignment across all functions.

- Remote Monitoring & Support: With AI-driven remote monitoring tools, manufacturers can oversee production operations, track inventory levels, and resolve issues from anywhere, ensuring continuity and reducing downtime, especially in the context of India’s vast and often remote industrial landscape.

- Knowledge Management & Continuous Learning: AI-powered workspaces foster continuous learning and knowledge-sharing, allowing employees to access real-time insights, best practices, and training modules, which drives employee productivity and skill development.

By embracing AI in Digital Workspaces, manufacturers in India can break down silos, improve cross-functional collaboration, and enhance the speed and accuracy of decision-making across the supply chain.

4. AI with Edge Computing and Cloud-Native Solutions for Manufacturing Supply Chains

In a country like India, where manufacturing operations often span large geographies and diverse environments, real-time data processing is essential. Integrating AI with Edge Computing and Cloud-Native solutions ensures scalable, low-latency decision-making, optimizing production lines, and enhancing supply chain efficiency.

- Edge Computing for Real-Time Production Optimization: AI at the edge enables real-time monitoring of production lines, quality control systems, and machinery performance, allowing immediate intervention to address issues before they affect the overall supply chain.

- Supply Chain Automation & Optimization: Our AI-powered Edge solutions provide manufacturing plants with autonomous systems to optimize inventory flows, track shipments, and streamline warehousing operations, ensuring timely deliveries and reducing manual labor.

- Scalable Infrastructure: By utilizing Cloud-native solutions, manufacturers can scale operations seamlessly across multiple sites, ensuring consistent performance and high availability of critical supply chain applications.

Through the integration of Edge Computing and AI, manufacturers can achieve enhanced flexibility, scalability, and resilience in their supply chains, ensuring they remain agile amidst changing market dynamics.

5. AI and Industry 4.0 in Indian Manufacturing

As Industry 4.0 technologies continue to revolutionize manufacturing, AI, IoT, automation, and big data analytics are transforming how supply chains operate and adapt. Manufacturers in India must embrace these innovations to stay competitive, reduce costs, and meet customer demands for higher-quality products and faster delivery.

- Smart Factories: AI-powered automation systems enable real-time process control and intelligent production planning, helping manufacturers optimize their production lines, reduce waste, and improve overall operational efficiency.

- Demand-Driven Supply Chains: Using AI-driven demand forecasting, manufacturers can align their production schedules with real-time market demand, reducing lead times and improving customer satisfaction.

- End-to-End Automation: From production to warehouse management and last-mile delivery, AI-powered systems optimize every stage of the manufacturing supply chain, ensuring greater operational efficiency and reducing human error.

By leveraging Industry 4.0 technologies, manufacturers can drive a digital transformation that maximizes efficiency, reduces costs, and improves sustainability in their supply chains.

Why Choose [Your Company Name] for AI-Driven Manufacturing Solutions?

At [Your Company Name], we offer AI-driven solutions designed to enhance every facet of your manufacturing supply chain. From production planning and logistics to inventory management and demand forecasting, we empower Indian manufacturers to adopt cutting-edge technologies that drive growth and resilience in today’s highly competitive global market.

Integrated Solutions for Manufacturing Supply Chains

Our comprehensive suite of AI-powered ERP, enterprise data management, and digital workspace solutions enables manufacturers to seamlessly integrate their entire supply chain ecosystem.

Data-Driven Insights for Operational Excellence

With real-time AI insights, manufacturers can make smarter decisions, optimize inventory management, reduce costs, and enhance operational efficiency.

Scalable, Cloud-Based Infrastructure

Our cloud-native solutions offer the flexibility and scalability needed to support growing manufacturing operations, ensuring performance, security, and availability across all stages of the supply chain.

Ready to Transform Your Manufacturing Supply Chain with AI?

Embrace AI-driven solutions to enhance supply chain visibility, streamline operations, and ensure on-time deliveries in India’s dynamic manufacturing sector. Contact us today to explore how our advanced technologies can drive operational excellence, reduce costs, and position your organization for long-term success in a rapidly evolving market.